Industrial Eyelets

Industrial Eyelets

GS Eyeleting System

The Most Versatile eyeleting system available- The GS system lets you choose from 72 sizes, graduated by 32nds of an inch in both length and barrel diameters

- GS eyelet sizes in stock in brass base material

- Nickel, black chemical, cadmium, electro tin, antiques and custom painted finishes and platings are available

- The GS system gives you the flexibility of using all lengths of the same barrel diameter without changing setting tools. This saves you time and money

- Most automatic feed machines can run all lengths of the same barrel diameter with easily interchangeable parts

- Siska Inc. also has a complete line of setting machines and over 80 years of expertise in building, modifying and repairing eyelet and grommet attaching machines.

- Most common applications for Industrial Eyelets are: print finishing, holsters and knife sheaths, electronics, medical and because of their versatility many other general eyelet applications.

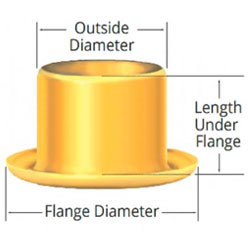

| Inches | Length Under Flange | |||||||||||||

| 2/32 .062 |

3/32 .093 |

4/32 .125 |

5/32 .156 |

6/32 .187 |

7/32 .219 |

8/32 .250 |

9/32 .281 |

10/32 .312 |

11/32 .344 |

12/32 .375 |

13/32 .406 |

14/32 .437 |

||

| Outside Diameter | .059 |

S-4GS 2-2 |

S-5GS 2-3 |

S-6GS 2-4 |

S-7GS 2-5 |

S-8GS 2-6 |

S-9GS 2-7 |

|||||||

| Flange Diameter | .105 | |||||||||||||

| Metal Thickness | .007 | |||||||||||||

| Outside Diameter | .089 |

L-11GS 3-3 |

L-12GS 3-4 |

L-12LGS 3-5 |

L-13GS 3-6 |

L-14GS 3-7 |

L-15GS 3-8 |

L-16GS 3-9 |

L-17 GS 3-10 |

L-18 GS 3-11 |

L-19 GS 3-12 |

|||

| Flange Diameter | .150 | |||||||||||||

| Metal Thickness | .009 | |||||||||||||

| Outside Diameter | .121 |

S-14GS 4-3 |

S-15GS 4-4 |

S-16 GS 4-5 |

S-17 GS 4-6 |

S-18 GS 4-7 |

S-18L GS 4-8 |

S-18XL GS 4-9 |

S-19 GS 4-10 |

S-20 GS 4-11 |

S-21 GS 4-12 |

|||

| Flange Diameter | .200 | |||||||||||||

| Metal Thickness | .0095 | |||||||||||||

| Outside Diameter | .152 |

S-23GS 5-3 |

S-24 GS 5-4 |

S-25 GS 5-5 |

S-26 GS 5-6 |

S-27 GS 5-7 |

S-28 GS 5-8 |

S-28L GS 5-9 |

S-29 GS 5-10 |

S-30 GS 5-11 |

S-31 GS 5-12 |

|||

| Flange Diameter | .245 | |||||||||||||

| Metal Thickness | .010 | |||||||||||||

| Outside Diameter | .183 |

S-32 GS 6-3 |

S-33 GS 6-4 |

S-34 GS 6-5 |

S-35 GS 6-6 |

S-35L GS 6-7 |

S-36 GS 6-8 |

S-37 GS 6-9 |

S-38 GS 6-10 |

S-39 GS 6-11 |

S-40 GS 6-12 |

S-41 GS 6-13 |

S-42 GS 6-14 |

|

| Flange Diameter | .290 | |||||||||||||

| Metal Thickness | .0105 | |||||||||||||

| Outside Diameter | .215 |

S-43GS 7-3 |

S-44GS 7-4 |

S-45GS 7-5 |

S-46GS 7-6 |

S-47GS 7-7 |

S-48 GS 7-8 |

S-49 GS 7-9 |

S-50 GS 7-10 |

S-51GS 7-11 |

S-52 GS 7-12 |

S-53 GS 7-13 |

S-54GS 7-14 |

|

| Flange Diameter | .340 | |||||||||||||

| Metal Thickness | .011 | |||||||||||||

| Outside Diameter | .246 |

S-55GS 8-3 |

S-56GS 8-4 |

S-57GS 8-5 |

S-58GS 8-6 |

S-59 GS 8-7 |

S-60 GS 8-8 |

S-61 GS 8-9 |

S-62 GS 8-10 |

S-63GS 8-11 |

S-64 GS 8-12 |

S-65GS 8-13 |

S-66 GS 8-14 |

|

| Flange Diameter | .385 | |||||||||||||

| Metal Thickness | .011 | |||||||||||||