Model B / USM B

Model B / USM B

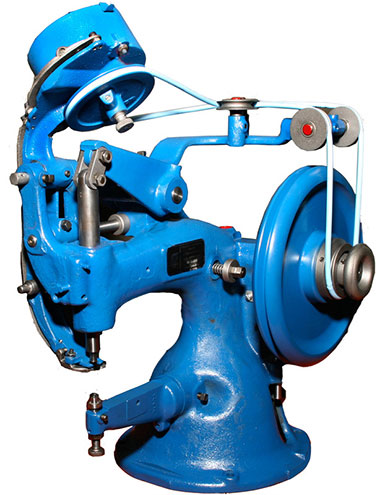

United Model B Auto Feed Electric Eyelet Setting Machine

The Model B is a standard duty, single revolution electric eyelet setting machine best suited for smaller eyelets in applications that are pre-punched (meaning there is already a hole in the material). The machine is a single feed machine which does not feed a washer. If your application requires a washer, it can be hand feed onto the bottom die. The throat depth on the machine is 7 inches making it ideal for pinwheel applications as well as knife sheaths and tydex holsters. Like all auto feed eyelet machines, the Model B is set up to run one barrel diameter size eyelet only. Different lengths of the same size barrel diameter eyelets will feed in this machine. ( see our Industrial Eyelet Page)

Additional eyelet feeders can be purchased to change eyelet sizes quickly and easily making this machine very versatile. A heavy duty machine stand is standard.

Size Capacity:

- 1/8 inch eyelet to #0 grommets

Advantages:

- Quick activation, quiet and built for high production run. The model B is especially good at running smaller eyelets.

Maintenance:

- Lubrication with 30wt motor oil before use is recommended

Optional Equipment:

- Interchangeable raceways to run different eyelets are available

- Mobile work stand with casters

- Work plate with back and side gauges

- Laser locating light

- LED table work light

- Hands Free electronic ring guard safety devise and palm button actuation are available

Specifications:

- Dimensions: 15 X 16 base, 22 inches high, mounted on table: 58 inches high

- Weight: 75 pounds

- Electrical requirement: 110 Volt AC single phase – standard wall outlet

- Motor Size: 1/3 HP

- Pneumatic requirement: none