Intro to setting machines and selection guide

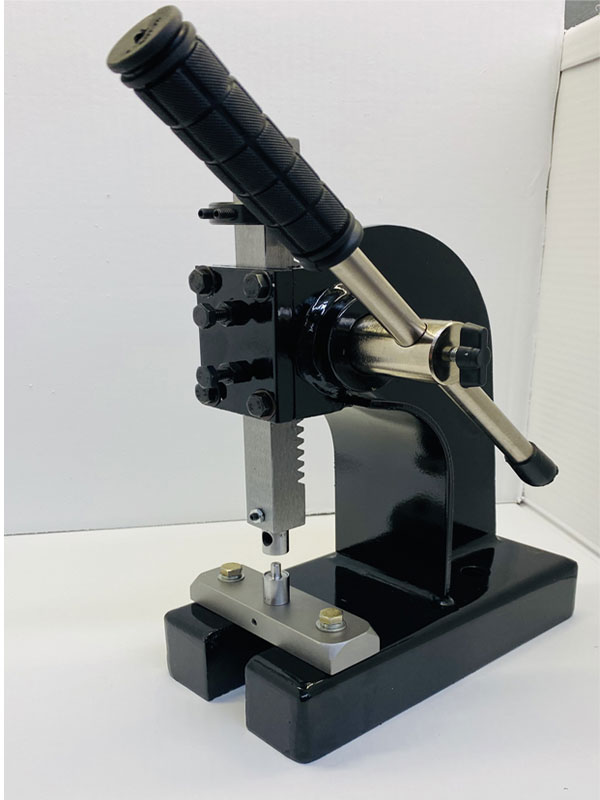

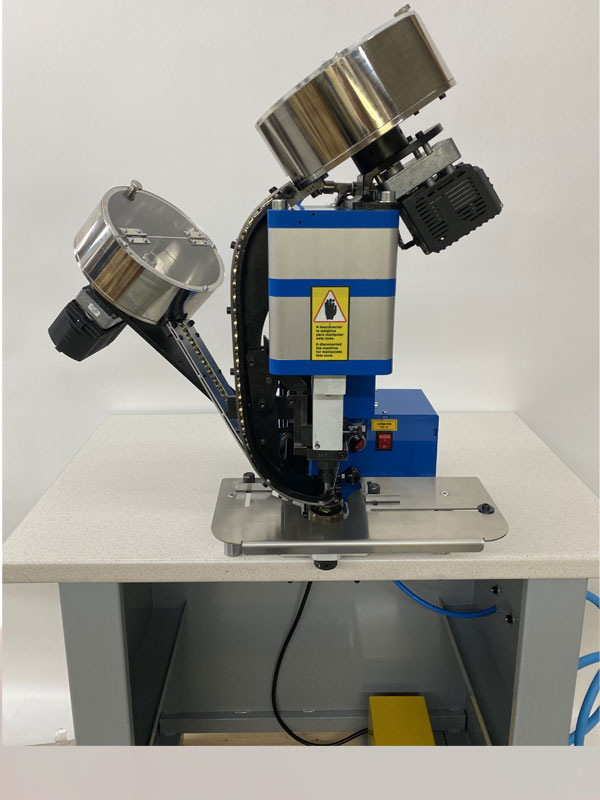

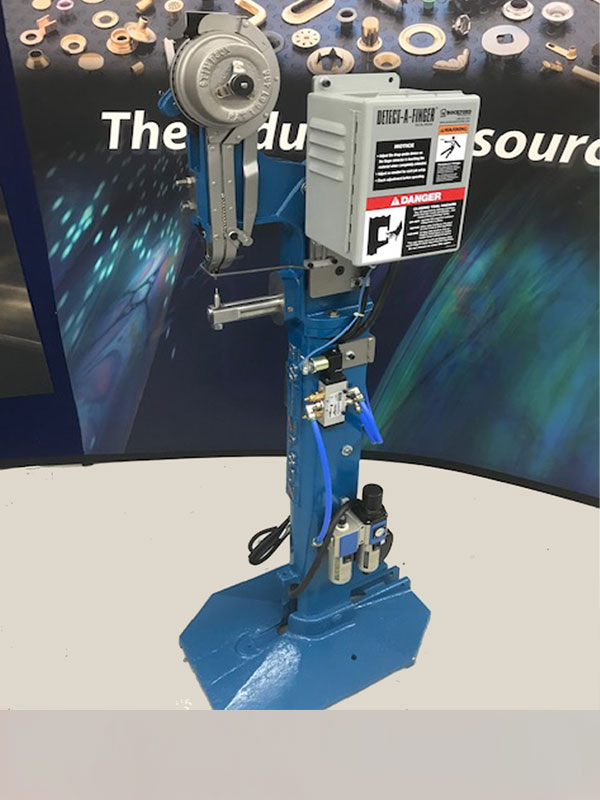

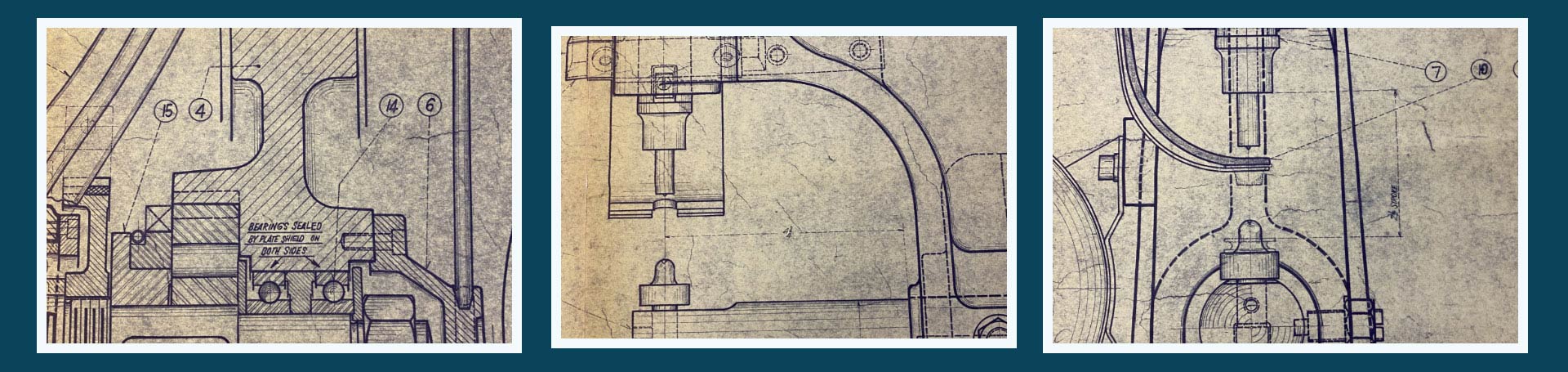

The fastening process involves two key elements: the fastener (eyelets, rivets, grommets, etc.) and the fastening equipment that performs the setting operation. The proper selection of the machine and the tooling that performs the setting operations are as crucial to efficient production as the choice of the fastener itself. The selection of a machine depends directly upon production volume requirements. The fundamental difference between the various models of fastening machines is their production volume capacity, and the range of fastener sizes that they are equipped to handle and set. Some machines are more suited to install smaller fasteners while others are capable of handling very large fasteners. Special machine modifications, such as tools and fixtures, can be made for standard machines to adapt them to special assembly requirements. Some machines are available with special arms, multiple adjustable center heads, and feed guides. The larger, more sophisticated machines are electrically powered and are available with one or more roadways. These models can be equipped with a variety of accessories; such as, right or left mounted roadways, special tooling and special compensators which help to eliminate breakage on fragile or variable thickness materials. Electric and pneumatic machines can be furnished with safety devices to protect the operator. Some models are available as either foot power, electric or pneumatic powered. Many machines can be furnished in bench models or mounted on a stand. Listed below are some categories for machine selection that are based upon the weekly volume of settings that need to be done: